Pipe Stand’s turning rolls are suitable for pipes and circular objects with a diameter ranging from 0.3 M – 4.26 M / 1′ to 14′ that can be lifted or lowered in a range from 762.0 mm – 1,219.2 mm / 30″ to 48″.

40 Ton Height Adjustable Tank Turning Rolls (Vessel Rotators) Specifications

| Load Capacity

(balanced) |

Driver: 18,143 kg / 40,000 lbs (20-ton)

Idler: 18,143 kg / 40,000 lbs (20-ton) |

| Diameter Range | 0.3 M – 4.26 M

1′ – 14′ |

| Footprint | 2,946.4 mm x 1,117.6 mm x 787.4 mm

116″ x 44″ x 31″ |

| Height Adjustability | 762.0 mm – 1,219.2 mm (top of wheel) Adjustable in 76.2 mm increments

30″ – 48″ (top of wheel) Adjustable in 3″ increments |

| Tractive Effort | Dual Drive, 3,946.25 kg / 8,700 lbs |

| Output Torque | 9,038 Nm

80,000 in-lbs |

| Power Requirements | 480 V, 3-ph |

| Rotation Speed | 127.0-1,270.0 mm/min

5–50 in/min |

| Equipment Mass | Driver: 1,202 kg / 2,650 lbs;

Idler: 771 kg / 1,700 lbs |

| Available Accessories | Hand Pendants: bidirectional with digital readout (Cabled); wireless style available (>110V models only)

Foot Switch: forward/reverse standard; variable speed style available on request Work Holding: Grippers, chucks, or specialized fixtures |

| Options | Input Power Options: as per standard spec or to customer requirements

Custom Height Range: to customer requirement Upgrade Controls: HMI touchscreens, full integration to Pipe Stand’s column boom welding manipulators |

40 Ton Height Adjustable Tank Turning Rolls (Vessel Rotators) Request a Quote

40 Ton Height Adjustable Tank Turning Rolls (Vessel Rotators) Product Information

Our height-adjustable turning rolls are widely used in various industries and other fields that concern pipes and pipe assembling. Serving as a tool for welding round seams of pipes, barrels, pressure containers, and other cylindrical workpieces. Pipe Stand’s turning rolls are an indispensable tool for shell fabrication shops.

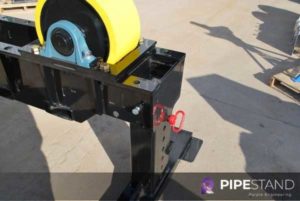

The extremely heavy-duty design of our turning roll ensures durability over years of use. With 20TRV-100/200 we can ensure increased production with reduced labor skill, lower work fatigue, and maximize the quality of welds using synchronized rotation. Pipe Stand’s height-adjustable turning rolls improve plant efficiency, welding automation and provide precise rotation of cylindrical workpieces. Additionally, they provide lesser usage of cranes reducing the idle time and polyurethane rollers that maintain constant centerline and accurate roll center changes. Using our turning rolls ensure minimum shell/job handling and seamless integration with manipulator applications.

Pipe Stand’s turning rolls are suitable for pipes and circular objects with a diameter ranging from 0.3 M – 4.26 M / 1′ to 14′ that can be lifted or lowered in a range from 762.0 mm – 1,219.2 mm / 30″ to 48″. The loading capacity reaches 20 tons which are dispersed equally on the driver and idler. Pipe Stand’s 20TRV-100/200 turning roll can be operated manually with hand pendants that are available cabled or wireless. Pipe Stand also offers other accessories and options, including different types of footswitches, grippers, casters, and other specialized fixtures that can be added to the customer’s request.

Perth and Brisbane Distribution Centres for Delivery Australia Wide Ordering Information

We carry stock in both our West Australian and our Queensland warehouses and can arrange delivery Australia wide. Some items are special order however we still have reasonable timeframes on delivery.

To arrange a quote please use the “Request a Quote” form. If you are looking for a specialty item or a custom build, please contact us directly with your specifications and one of our engineering team will be able to assist.

Manufacturer Information LJ Welding Automation

Pipe Stand is Australia’s leading distributor of LJ Welding products, from Pipe Stands, to Cable Reel Rollers, and everything in between.

LJ Welding Automation based out of Edmonton, Alberta, Canada, has been delivering top-quality welding positioners, vessel rotators, pipe and tank turning rolls, and welding automation equipment to the welding and fabrication industry for decades.

All equipment from LJ Welding Automation CSA/UL certified in-house in their CSA-compliant facility (CE certifications available on request). Equipment is APEGA certified (Engineering), with a full engineering department including a variety of professional Mechanical Engineers, CAD Technicians, Controls & Computer Programming engineers.

3D SOLIDWORKS modelling is used to create 3D drawings for customers to view prior to custom manufacturing and their state of the art facility utilizes robotics and full CNC machining centres to maximize productivity, which is returned in value to customer through lower production costs.